Have you ever encountered white smoke or steam while printing? You’re afraid that it will explode in the next second, so you stop printing and power off immediately. In fact, this is not a problem caused by the printer, but that of damp printing paper.

During the rainy and humid season, the printing paper are easily getting damp. This is a common problem, and it has effects on the print quality. What are the effects?

1. Paper jam, especially the paper glued on the photoconductor (drum). They can’t be separated, which affects copy efficiency.

The moisture content of the entire surface of the damp paper is unevenly distributed. Under the binding force of water molecules and fibers, the original paper are deformed, and the deformed printing paper are sent to the pickup shaft. The uneven paper get stuck on the pickup shaft, causing paper jam.

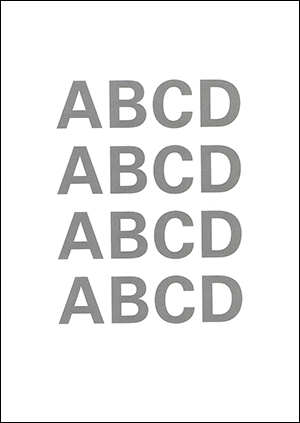

2. Low print density

As the water content of the damp paper is high, the toner are diluted during fixing. Then the printing density is lower, and the printed words look a little lighter.

Low print density normal

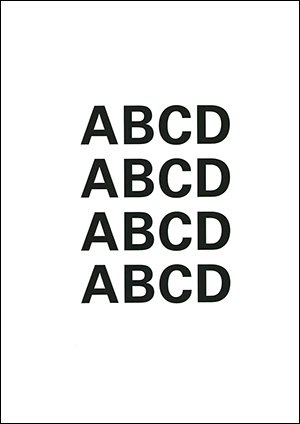

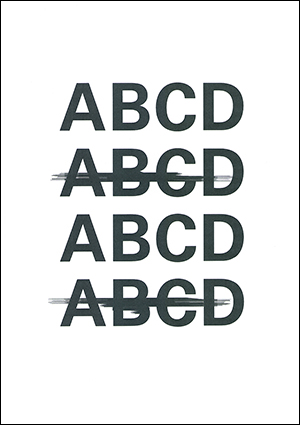

3.Obvious backgrounding

The damp printing paper may cause the leak of electricity during the printing process, leading to an obvious backgrounding.

bottom ash normal

4. Horizontal or vertical bandings on the printed paper

The main reason is that moisture reduces the toner transfer ability, and decreases the charge given to the paper by the transfer roller, either. The disordered charge arrangement results in horizontal or vertical bandings.

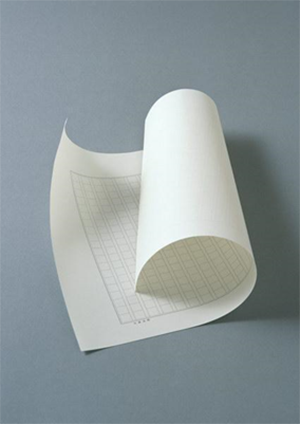

5.Bent printed paper

The printer is heated during the printing with a heating device (fixing assembly). After the damp paper is heated, it is easy to deform due to the inconsistent frequency of loss of water shrinkage, and then the printed paper becomes bent.

Solutions:

1. Put printing paper in a closed cabinet with desiccant.

2. Do not unpack the printing paper before use; in an environment with high humidity, the unused copy paper should be put back in the packaging bag; and use the paper based on your need.

-

Consumables

- Printers

- Industries

- Innovation

-

Partners

G&G Partner ProgramCo-Innovating Tomorrow Read More >

- About Us

-

Contact Us