-

Consumables

- Printers

- Industries

- Innovation

-

Partners

G&G Partner ProgramCo-Innovating Tomorrow Read More >

- About Us

-

Contact Us

In an era where sustainability and cost-efficiency are paramount, we at G&G are proud to offer remanufactured toner cartridges that meet the highest standards of quality and environmental responsibility. Our commitment to excellence in remanufacturing ensures that our customers receive reliable products without compromising on performance.

The Remanufacturing Process

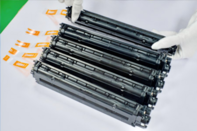

The journey of G&G remanufactured toner cartridges begins with a rigorous inspection, sorting, and grading process. Skilled technicians meticulously evaluate all incoming raw materials to ensure that only superior empty cartridges are selected for reuse. Cartridges that do not meet our high standards are broken down for their plastics and metals and sent to accredited recyclers, thereby minimizing waste and promoting sustainability.

Once selected, the empty cartridges undergo a careful dismantling process using specially designed tools to avoid toner contamination. This step is crucial to maintaining the integrity of the remanufactured toner cartridges. Following this, extensive matching tests are conducted under various conditions to ensure that all components work harmoniously throughout the cartridge's lifecycle.

Quality Assurance Measures

Quality is at the forefront of our remanufacturing process. After dismantling, all key components—including OPCs, wipe blades, doctor blades, magnetic rollers, and PCRs—are tested for performance. This thorough examination allows us to identify any parts that require replacement, ensuring that only the best components are used in our remanufactured toner cartridges.

Automated toner filling and vacuuming processes are employed to fill each cartridge with premium toner powders. This automation not only enhances efficiency but also ensures that no residual toner remains on the casing. Each cartridge is then sealed with a strip to prevent any leakage, further ensuring reliability.

Our assembly process involves well-trained technicians who follow strict protocols and cross-checks at every step. This attention to detail extends to chip inspection, where microchips are installed to guarantee compatibility with the printers our cartridges will be used.

Comprehensive Testing and Packaging

Every remanufactured toner cartridge undergoes a thorough post-testing procedure as part of our production line. This includes visual inspections by trained staff to catch any discrepancies, ensuring that each cartridge meets our high-quality standards. Additionally, 2% of every production batch is sampled and tested with a page run of over 200 pages, providing further assurance of performance.

Finally, each cartridge is heat-sealed in a light-proof bag and carefully packaged in well-padded boxes for dispatch. This meticulous packaging protects the sensitive components and ensures that our remanufactured toner cartridges arrive in excellent condition.

Conclusion

In conclusion, G&G remanufactured toner cartridges offer a sustainable and cost-effective solution for all your printing needs. Our rigorous remanufacturing process, combined with comprehensive quality assurance measures, ensures that you receive high-quality products you can trust. By choosing G&G, you are not only making a smart choice for your business but also contributing to a more sustainable future. Trust G&G for your remanufactured toner cartridge needs and experience the difference in quality and performance.